Challenge

The client previously struggled to guarantee accurate and efficient quality checks for their pumps, gearboxes, and salt production. Their reliance on manual checklists presented significant challenges.

Prone to Errors: The manual process was susceptible to human error due to the possibility of inaccurate data entry, inconsistencies, and potential oversights.

Limited Reporting: Real-time reporting capabilities were absent, hindering the ability to gain immediate insights into quality control data and identify potential issues promptly.

Hindered Workflow: Manual checklists hampered workflow efficiency. This could involve time-consuming processes, repetitive tasks, and potential delays in identifying and addressing quality concerns.

These limitations ultimately hampered the client’s ability to maintain consistent quality standards, respond to issues swiftly, and optimize their production processes.

Solution

- Customized Checklist Templates: Sunny Street’s platform allows for the creation of customized checklist templates tailored to the clients specific needs. These templates encompass critical components such as gearboxes, pumps, cooling systems, bearings, axial play, shaft integrity, backlash readings, couplings, and drive ends.

- Mobile-Friendly Interface: The mobile-friendly interface enables technicians to conveniently access and complete the checklists on-site, enhancing flexibility and efficiency in the inspection process.

- Dynamic Data Capture: Sunny Street’s dynamic form capabilities ensure accurate data capture by allowing technicians to record readings and observations directly on their mobile devices. This facilitates real-time data entry and reduces the risk of transcription errors associated with manual processes.

- Automated Analysis and Tracking: Upon submission of the checklists, Sunny Street automates the analysis and tracking of inspection data. The platform provides real-time insights into equipment conditions, enabling proactive maintenance and minimizing the risk of unplanned downtime.

- Comprehensive Reporting: Sunny Street generates comprehensive reports summarizing inspection findings and recommendations. These reports are easily accessible to supervisors and management, facilitating informed decision-making and continuous improvement initiatives.

- Workflow Integration: Sunny Street seamlessly integrates with the clients existing workflow, ensuring smooth coordination between inspection tasks and follow-up actions. Task assignments and notifications keep relevant stakeholders informed and accountable throughout the inspection process.

- Centralized Data Management: All inspection data is securely stored and centralized within Sunny Street’s platform. This centralized repository simplifies data retrieval, fosters transparency, and facilitates compliance with regulatory requirements and internal quality standards.

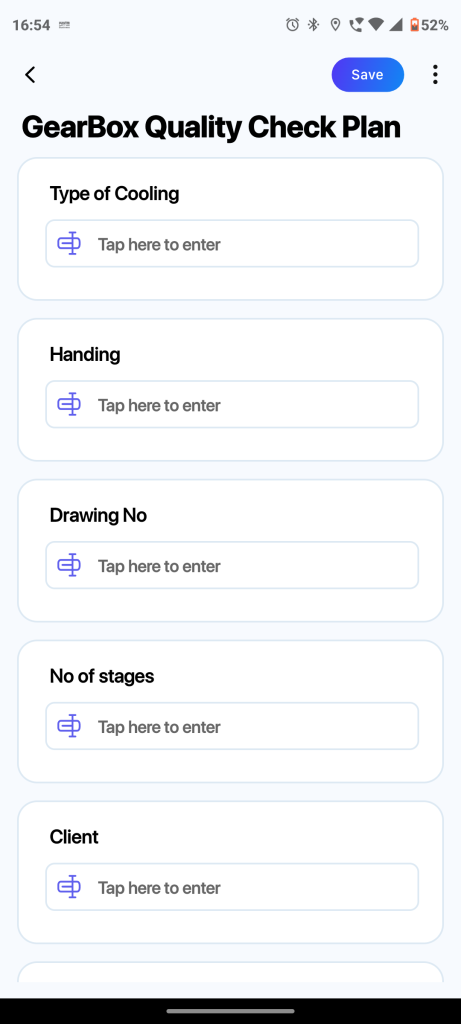

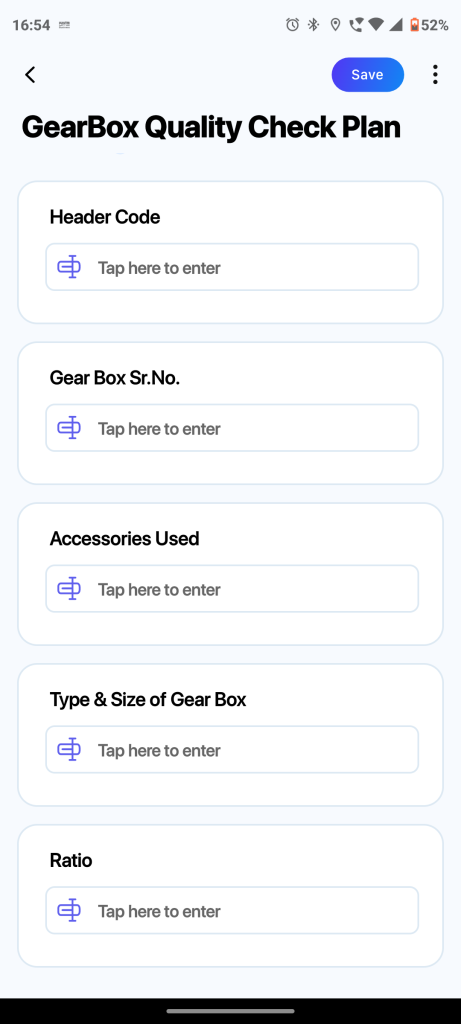

Mobile App Screens

Gearbox Quality Checklists

The application offers four checklists for Gearbox Quality Check. Users can access one general checklist and three model-specific checklists populated with default values.

- Users select a model number to open the corresponding checklist.

- Technicians enter values manually for all fields in the chosen checklist.

- Each model has its predefined default values displayed in the checklist.

- Admins can add new models and their default values through both mobile and web interfaces.

Pump Quality Checklists

The application provides four checklists for Pump Quality Check. Similar to gearboxes, there is one general checklist and three model-specific checklists with pre-populated defaults.

- Users select their desired model to open the relevant checklist.

- Technicians manually enter values for all fields within the chosen checklist.

- Each model has its specific default values listed within the checklist.

- Admins have the ability to add new models and their default values from both mobile and web interfaces.

Salt Checklists

The application presents four checklists for Salt Quality Check. This follows the same structure as gearboxes and pumps

- Users select the model number to access the corresponding checklist.

- Technicians manually enter values for all fields within the chosen checklist.

- Each model has its unique default values displayed in the checklist.

- Admins have the capability to add new models and their default values through both mobile and web interfaces.

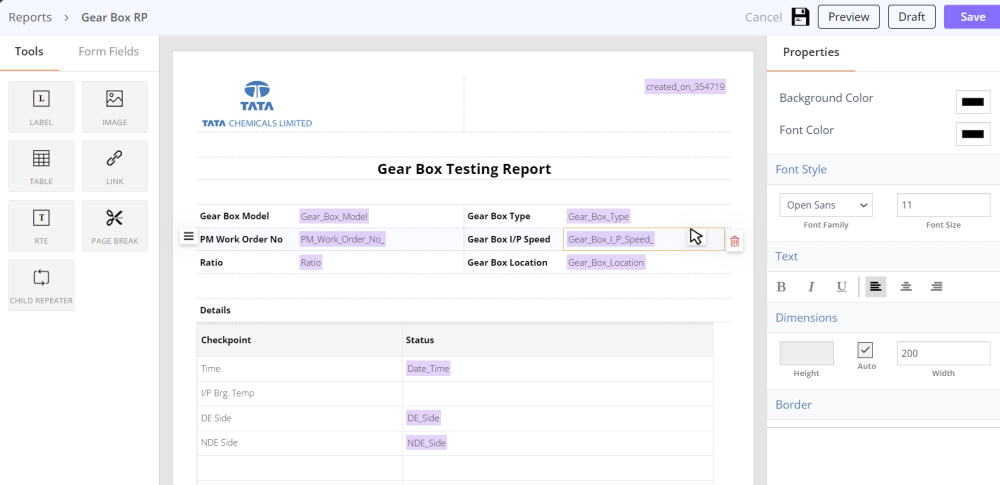

Report

Gear Box

- A PDF report will be generated after the submission of each checklist and will be sent to the preconfigured supervisor/manager.

- This email recipient can be changed/updated upon request.

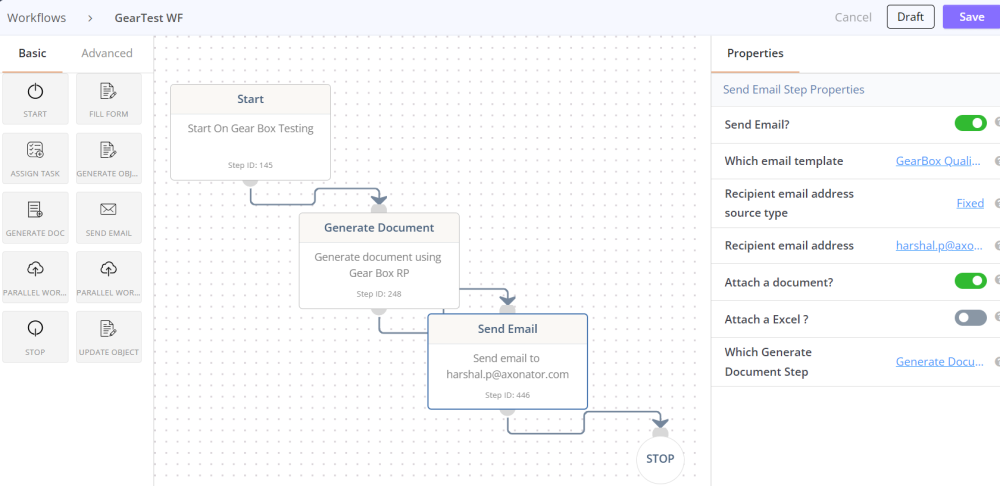

Workflow

Gear Box

The system should display specified default values in the checklist based on the model selection by the user. The system will send an email notification with an attached PDF report to the supervisor/manager after the checklist submission.

Results

Sunny Street’s comprehensive features, including the mobile form builder, workflow automation, report generation, notifications, dashboards, and task escalations, provided the client with a robust solution to streamline their quality control processes.

We were struggling with manual data entry and paper-based checklists until Sunny Street came to our rescue. The platform's mobile form builder, workflow automation, and reporting features have streamlined our maintenance processes. The real-time visibility and standardized procedures have significantly improved our efficiency. Sunny Street has proven to be a game-changer for us, helping us provide tech-savvy, customer-centric retail experiences seamlessly.

30x Time Saved

Reduction in Quality Check Time

20x Less Errors

Decrease in Data Entry Errors

50x Efficiency

Improvement in Workflow Efficiency

40x Accuracy

Increase in Data Accuracy